Loading ....

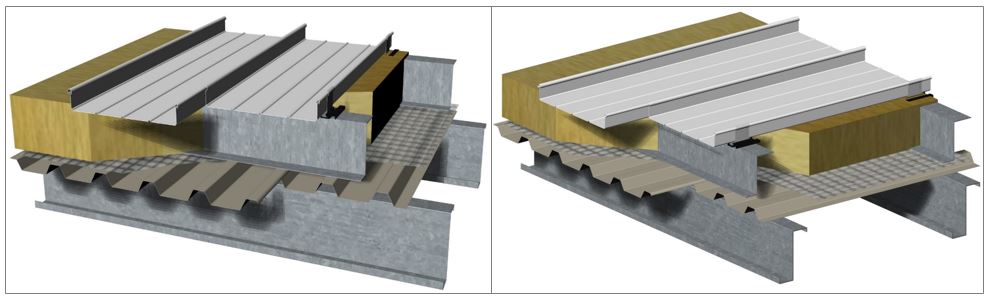

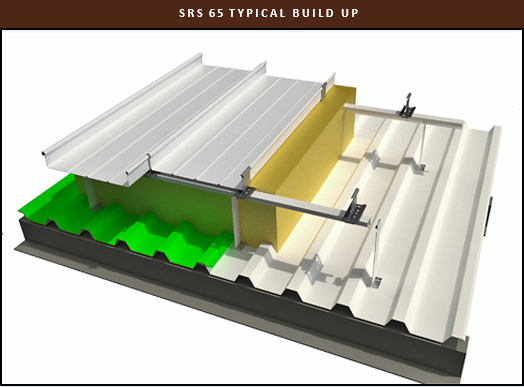

SRS65 panels are engineered for the design flexibility architects require and can be used on a wide spectrum of buildings. These panels can accommodate complex roof configurations, allowing smooth transitions between other building elements.

From manufacturing facilities to beachside resorts, SRS65 panels offer exceptional aesthetic flexibility to meet most any project requirement and design theme.

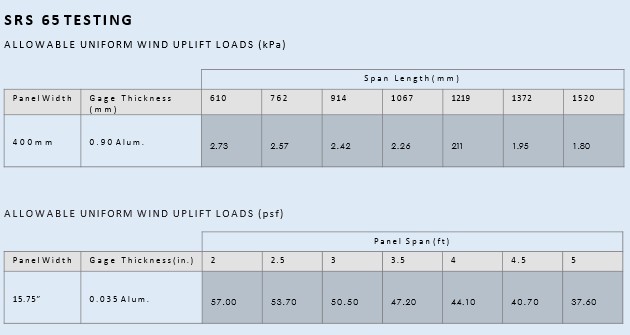

Notes:

Underlined values tested in accordance with COE Guidespec and ASTM 1592.

Allowable Uniform Loads include a 1.65 safety factor against panel failure. No increase for wind permitted.

Fastener pullout calculations must be performed for job specfic minimum support thickness.